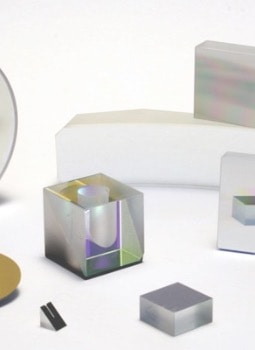

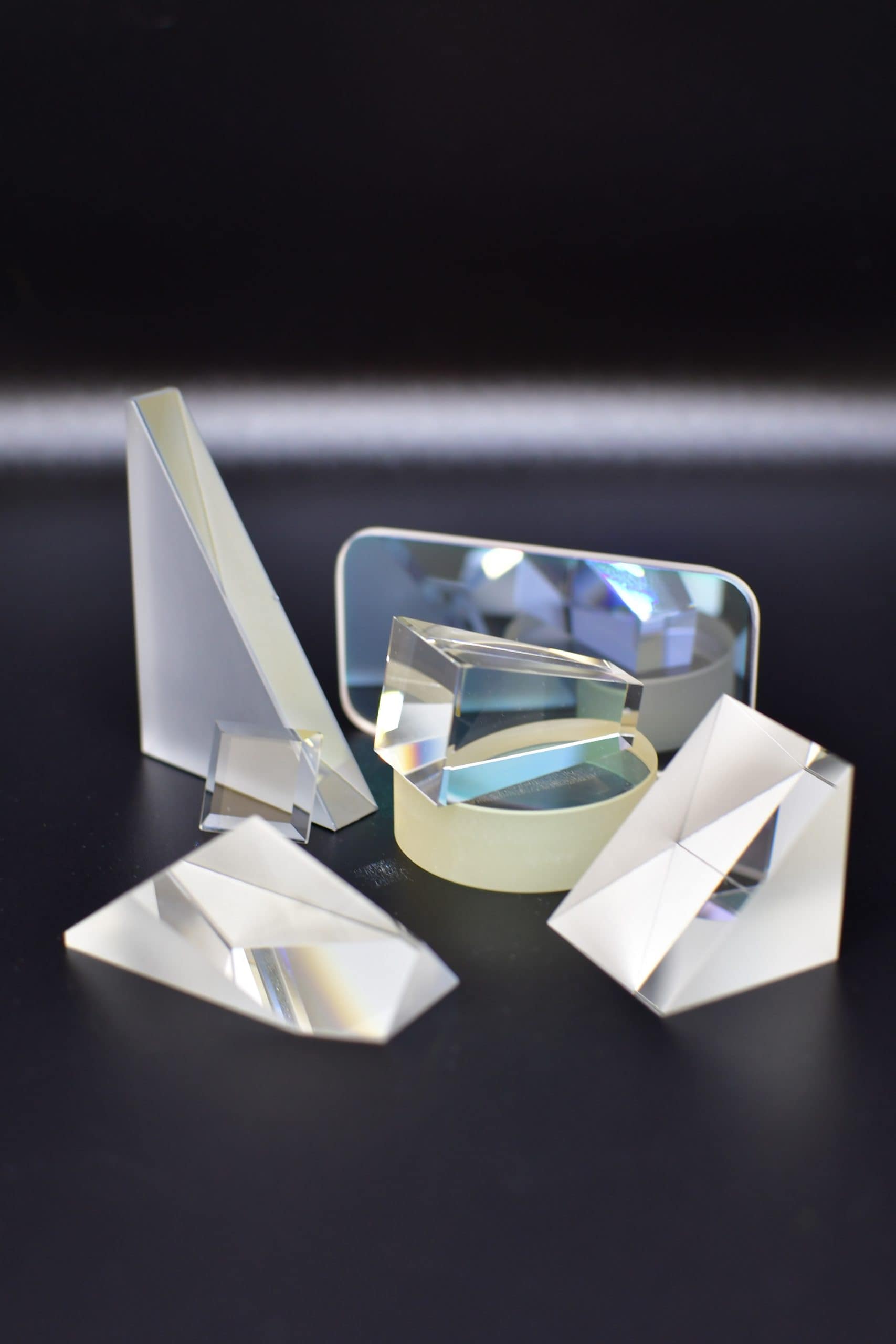

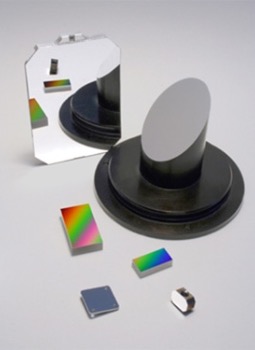

Optical Components

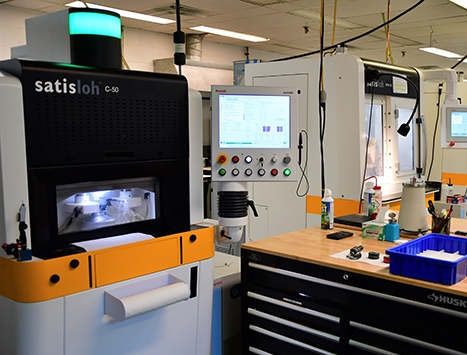

Our Custom Manufacturing Capabilities

Sub-Assemblies

Prototypes

Custom Solutions

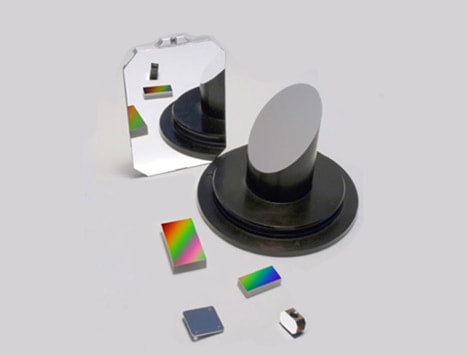

We recognize that many of our customers’ programs are on tight schedules and optical components can often be the longest lead-time item in a system. In many cases, such as optical coatings or simple lenses, windows, mirrors, and prisms, our company has delivered finished products in days and not weeks.

OEM Support

The OPCO OEM Lifecycle Support Program was established to support your company’s success in designing, developing and delivering cutting edge products to your customers.

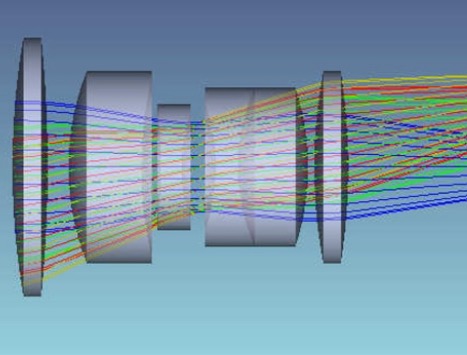

Optical Sub-assemblies

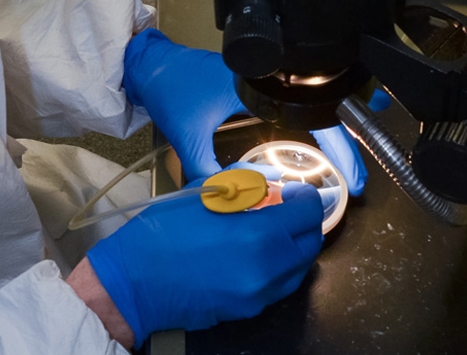

The optical professionals will provide contract manufacturing services from the most simple lens barrel to a fully integrated optical sub-assembly.

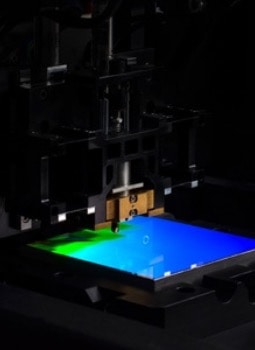

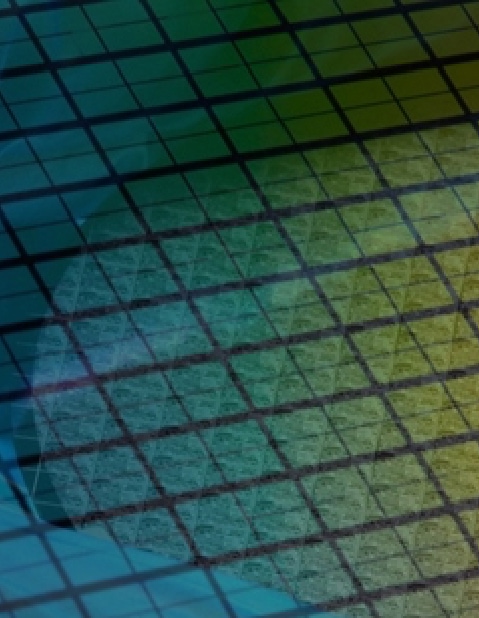

Replication

Optical Replication Provides Cost-Effective, Volume Production of Complex Optical Surfaces

Quick Turn Prototyping

To support our customers, OPCO offers a Quick Turn Prototype Optics service that can deliver finished products in 1-2 weeks ARO. This service is dependent upon the complexity of the product, availability of raw material, and also may be dependent upon tooling.

Industries We Serve

For more than 4 decades, we're proud to serve customers across a wide array of scientific and industrial applications, including:

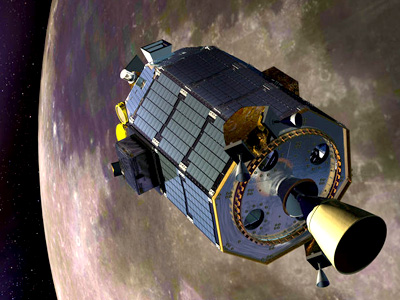

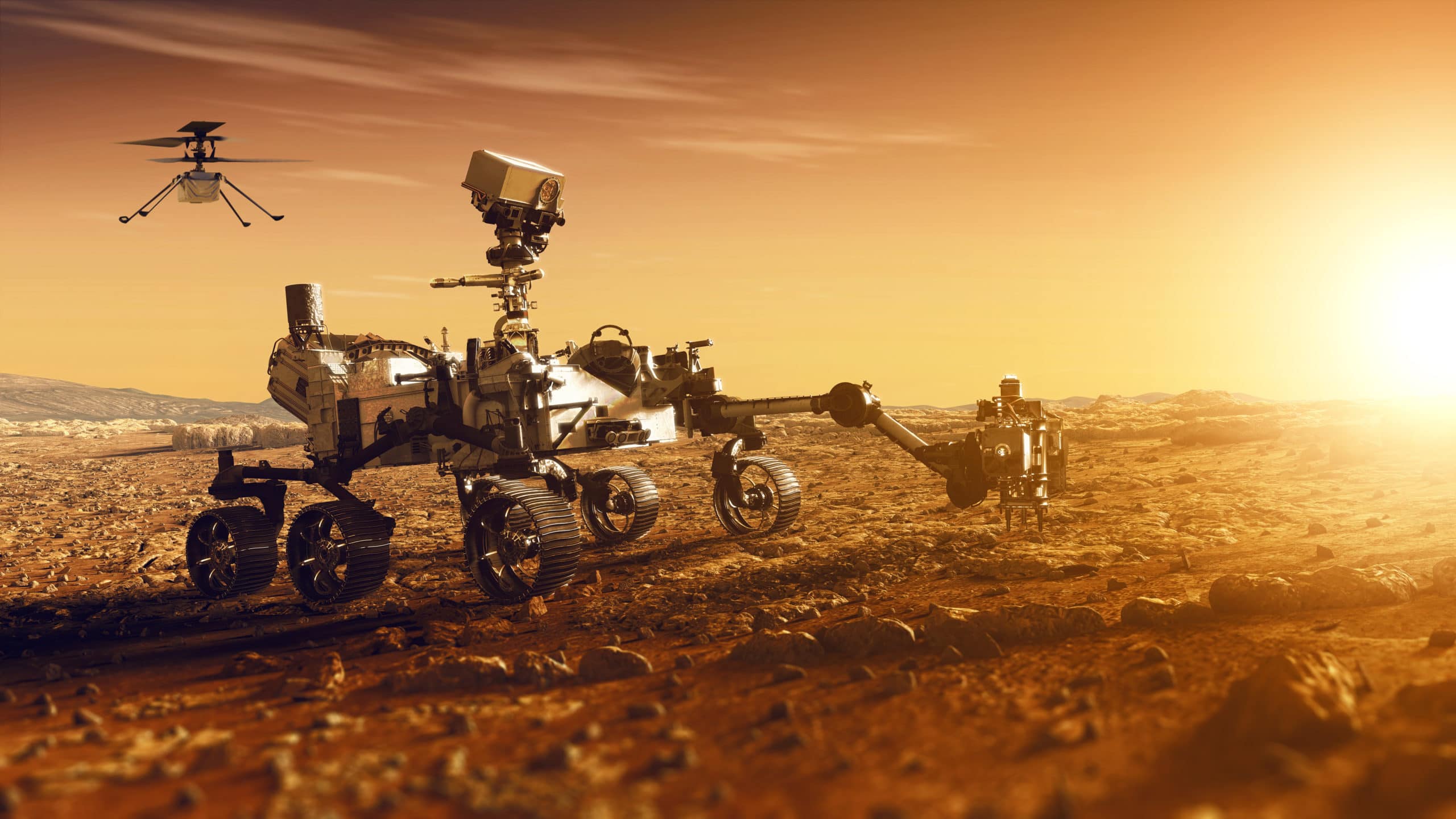

Space Exploration

Life Sciences / Medical

Spectroscopy

Aerospace/Defense

Working With Us

- Scope of capabilities and product experience

- Prototyping and optical component development services

- ITAR registered

- Over 40 years of optical design and manufacturing experience

Ready To Start Your Next Project?

Contact us now for more information.