Are you seeking top-notch optical prototypes within a strict timeline? OPCO Labs is at your service with our transformative Quick Turn Prototype Program. We pioneer in fabricating and delivering optical components faster than the industry norm, setting your projects on the fast track to completion.

Unlike the majority of our competition, our typical turnaround timeframes are significantly condensed, aiming to have your custom-made optics in your hands in just one to two weeks. This rapid response is contingent upon the intricacy of the product, the immediate availability of raw materials, and the requisite tooling.

Our program’s cornerstone is our understanding that your projects cannot afford to languish in waiting periods. Optical components frequently serve as the system’s longest lead-time item, and we’re here to trim that delay, keeping your venture smoothly on course.

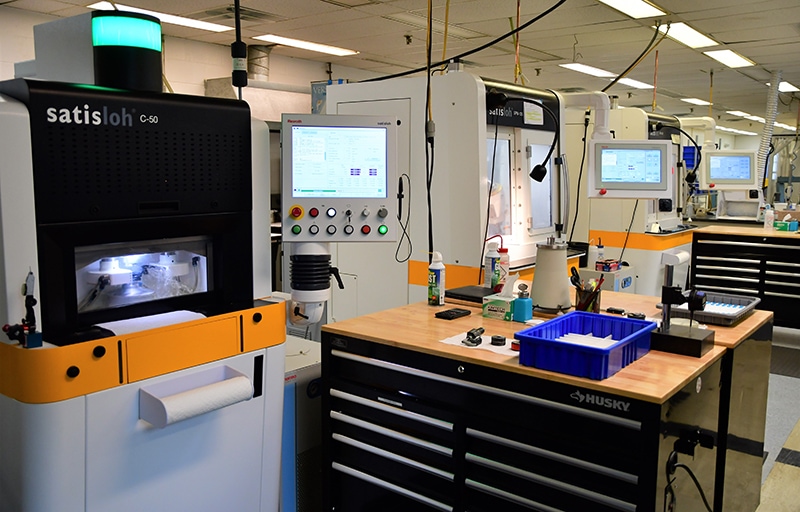

Serving Your Custom Needs with State-of-the-art Facility

Located in Massachusetts, our state-of-the-art facility is a hub of innovation and precision, enabling us to cater to your project’s unique needs efficiently. We specialize in providing custom optical coatings, simple lenses, prisms, mirrors, and windows that not only meet but exceed your expectations. Our commitment to your success goes beyond offering standard, off-the-shelf solutions. Instead, we serve as your reliable partner in crafting bespoke optical prototypes, meticulously designed and developed to align with your project’s specific requirements.

Our facility houses the latest in optics technology, staffed by a team of highly experienced professionals dedicated to achieving the highest standards in optical production. With a keen eye for detail, they work tirelessly to ensure each product mirrors the quality and precision that OPCO Labs is renowned for.

As a vertically integrated manufacturer, OPCO Labs takes pride in managing every aspect of production in-house. This includes everything from initial design to final assembly, ensuring stringent quality control at each stage. Our integrated approach enables us to maintain our speedy turnaround times, providing you with the optical prototypes you need without any undue delays.

Guaranteeing Quality Optics, Rapid Delivery

We have an established track record of providing finished products such as optical coatings, simple lenses, mirrors, windows, and prisms within weeks. The inherent value we provide extends beyond quality optics. Our ability to meet demanding schedules has made us the partner of choice for businesses seeking quick-turn prototype services.

Please note that an additional expedite fee may be applicable for our Quick Turn Prototype Program, considering the swift, reliable service we deliver. To discuss your requirements and timeline, reach out to us. We’re committed to delivering the optics needed to support your project on time, every time.

Your Prototyping Partner Awaits

Ryan at OPCO Labs eagerly awaits your call to discuss how we can tailor our turnaround times to expedite your prototype development.

Transform your innovative visions into reality with OPCO Labs’ Quick Turn Prototype Program. Allow us to deliver superior, custom-made optics at unmatched speeds, propelling your projects to new heights. Dive into the future of optics with us today.