OPCO can design and develop custom ruled diffraction gratings masters to suit any application requirement.

These ruled diffraction grating masters provide the “master” for use with the OPCO replication process and will enable the production of exact copies in any size / shape needed to support the OEM customer.

Most replicated ruled gratings produced today rely on masters created by decades old ruling engine technology; many of these masters were ruled more than 40 years ago.

Because of our technologically superior mechanical design, OPCO’s replicated gratings created from masters ruled on our new engine are demonstrating high efficiency, low scattered light, no periodic errors, and zero ghosts.

Contact Ryan at OPCO to discuss your requirements for grating masters.

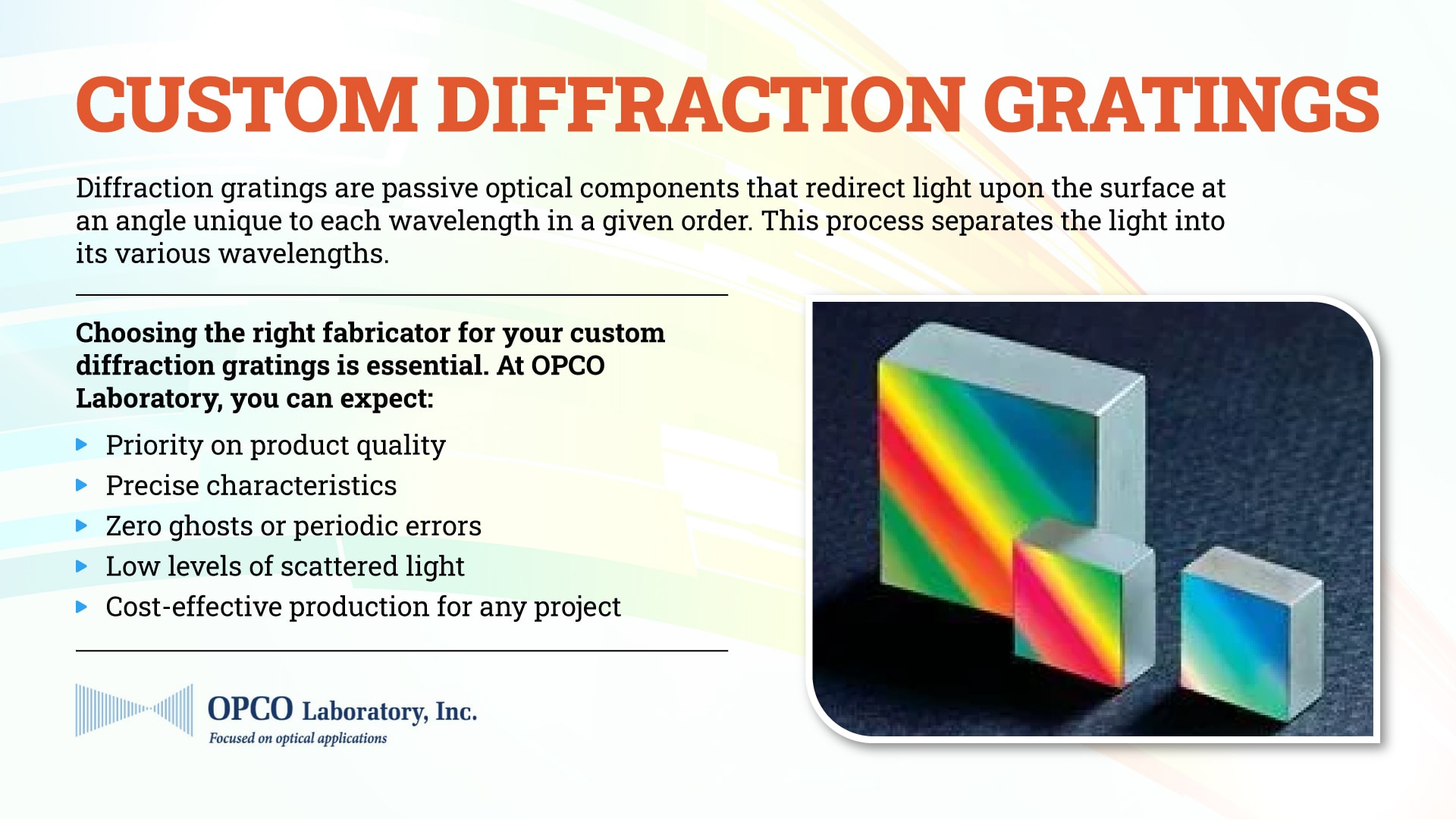

Custom Diffraction Gratings

Diffraction gratings are specialty components that separate beams of white light (input) into component wavelengths (output). The separation occurs when light is redirected from the surface of the grating at a specific angle based on the specific properties of the light and the grating. Custom diffraction gratings come in different grades to accommodate applications that require different degrees of fineness and sensitivity.

At OPCO Laboratory, Inc., we specialize in high-quality, custom diffraction gratings. We design and fabricate custom-made master gratings to accommodate new optical applications as well as ruled gratings from our extensive library of master gratings. Each of our masters is built to allow for virtually identical replication to suit precise applications.

Custom Grating Masters

Custom grating masters are the original fabrications used to duplicate additional, exact copies of the diffraction grating. They are designed and constructed to meet the needs of advanced processes, new equipment, and more. At OPCO Laboratory, our state-of-the-art equipment and experienced design and fabrication team can create custom grating masters with increasingly complex properties, including:

- Dual blaze wavelengths

- Specific blaze wavelengths within narrow tolerances

- Any requested groove frequency

- Custom ruling

Each master is engineered with the replication process in mind so our clients can obtain equally high-quality replications for use in additional equipment and locations. We manage every stage of production, from design and refinement to machining, grinding, and polishing, in-house to ensure every product achieves the highest standards. We perform stringent testing on every grating for complete quality assurance. Our team is capable of replicating custom grating masters and reverse engineering existing custom gratings for OEM clients.

Custom Grating Replications

Replica diffraction gratings are nearly identical to the master grating from which they were created. However, replications are much more cost-efficient than using master gratings while possessing all the same dimensions, properties, and capabilities of the master. The cost savings come from the replication process which can be done in a fraction of the time required for master grating production.

Many replications produced today still utilize masters that were created decades ago, but replications created using masters produced on OPCO’s technologically advanced new ruling engine exhibit higher optical tolerances and accuracy levels. OPCO Laboratory is a leading provider of replication services and we ensure that the original designs are never lost or compromised.

Grating Specifications

Our team can create custom grating masters and ruled diffraction grating replications with the following properties and specifications:

- Surface Accuracy: λ/4 typical

- Materials: Fused silica, aluminum, Borofloat®, Zerodur®, ceramics, and more

- Thickness: ≥ 1mm

- Dimensions: 5mm to 100 mm in length

- Shape: Round, square, rectangular, or custom

- Wavelength Scope: UV to mid-IR

- Grooves/mm: 30 to 3600

- Space Qualified: Currently utilized on Mars ROVER ChemCam Spectrometers

Benefits of Custom Diffraction Gratings

Choosing the right fabricator for your custom diffraction gratings is essential. At OPCO Laboratory, we prioritize product quality. Our new engine creates highly efficient and accurate gratings with no risk of cosmetic imperfections typically found in replications. We are a leading provider of mechanically and visually superior diffraction gratings with precise characteristics, zero ghosts or periodic errors, and low levels of scattered light. Each product has blaze or dual blaze wavelengths and a tuned groove frequency for optimal performance. Our fabrication processes allow for cost-effective production for any project.

Diffraction Grating Applications

We serve clients across diverse markets. Some of the applications of our custom diffraction gratings include:

- Amplitude gratings

- Beam scanning

- Laser

- Metrology

- Mirrors

- Monochromators

- Precision optical components

- Spectrometers

Custom Optical Solutions from OPCO Laboratory, Inc.

High-quality master optical gratings are the foundational piece for creating replications you can rely on for optical applications and consistent output across industries. OPCO Laboratory is an ITAR-registered facility, and our team of expert designers and fabricators can design and create custom gratings for virtually any application as a custom optics manufacturer. Contact us today to learn more about our capabilities or request a quote to start your order.