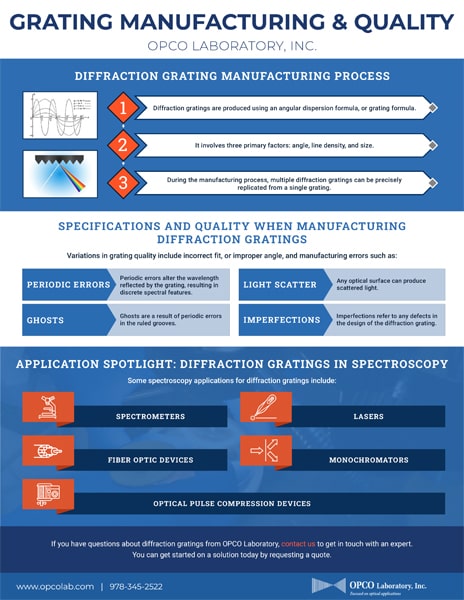

Diffraction Grating Manufacturing Process

Diffraction gratings are produced using an angular dispersion formula, or grating formula. It involves three primary factors: angle, line density, and size. The angle of incidence, angle of diffraction, and order of diffraction are components of the grating formula and must be precisely calculated to ensure the highest possible grating quality.

During the manufacturing process, multiple diffraction gratings can be precisely replicated from a single grating. This initial grating is referred to as the master grating. Using replication processes, the size, shape, and topographical features of the master grating are transferred onto another substrate, resulting in a replica diffraction grating that meets even the tightest tolerance requirements. Depending on the needs of each application, an existing stock grating may be used. If there is no master from which gratings can be produced, a custom master grating must be produced. Custom-fabricated master gratings meet the requirements of unique designs and newer equipment.

Specifications and Quality when Manufacturing Diffraction Gratings

Achieving the highest possible quality grating master has the most significant impact on diffraction grating quality. When creating custom master gratings, it’s especially critical to check the measurement from the angular dispersion formula are accurate and precise before creating the grating master.

Variations in grating quality include incorrect fit, or improper angle, and manufacturing errors such as:

- Periodic errors: Periodic errors alter the wavelength reflected by the grating, resulting in discrete spectral features such as offset peaks in the distribution of the focal plane.

- Ghosts: Ghosts are a result of periodic errors in the ruled grooves. Ghosts appear as false lines in the grating spectra.

- Light scatter: Any optical surface can produce scattered light. Major contributors to scattered light include light leaks from baffles.

- Imperfections: Imperfections refer to any defects in the design of the diffraction grating, including inaccuracies in groove spacing, groove depth, and surface roughness.

Master gratings produced using OPCO’s new ruling engine feature fewer imperfections than many other grating options. Our technologically superior ruling engine produces exceptionally accurate results.

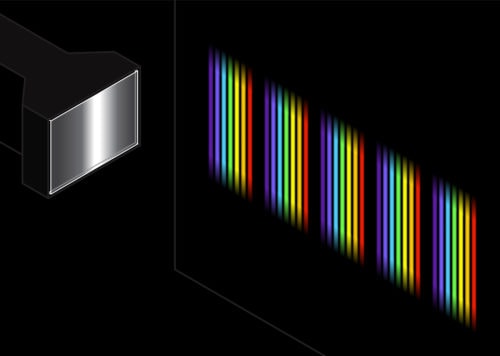

Application Spotlight: Diffraction Gratings in Spectroscopy

- Spectrometers

- Lasers

- Fiber optic devices

- Monochromators

- Optical pulse compression devices

Learn more about gratings for spectroscopy applications here.

Diffraction Gratings and Optical Components from OPCO Laboratory, Inc.

With over 40 years of experience in optical design and manufacturing, OPCO Laboratory, Inc. is an industry leader in developing superior optical solutions. As an ITAR-registered company, we produce diffraction gratings that meet all the requirements of highly specialized applications. From component design to fabrication, assembly, and testing, we handle all stages of the manufacturing process, ensuring reduced cost and lead times.

You can learn more about our stock and custom grating products by visiting our gratings overview page. If you have questions about diffraction gratings from OPCO Laboratory, contact us to get in touch with an expert. You can get started on a solution today by requesting a quote.