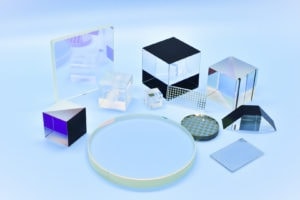

Optical components are parts of optical systems that are responsible for managing light. Optical components come in many shapes and sizes, and each optical component serves a specific function, from light splitting to filtering, reflecting, and polarizing. While there are hundreds of unique optical components, they typically fall into two categories: transmissive and reflective.

Reflective optical components include mirrors, while transmissive optical components include complex configurations like beamsplitters and prisms, which we will discuss in this article. Beamsplitters are an incredibly powerful optical component used in telecommunications, fiber optics, and cameras, and they have various applications across industries that make them an incredible optics tool for manufacturers.

What Is a Beamsplitter?

Beamsplitters are optical components that perform their named duty—splitting a beam. While beamsplitters fall into the transmissive category of optical components, they technically perform both reflecting and transmitting. Typically, beamsplitters split incident light into two beams based on a specific intensity (e.g., 40% reflection and 60% transmission). This ability to control transmissive and reflective intensity makes beamsplitters ideal for cameras, laser systems, security components, and measurement tools.

The most common beamsplitter construction involves two right-angled prisms that are glued together to form a cube. When light is incident on the beamsplitter, some of the light is reflected at a 90-degree angle. This separates the reflected and transmitted beams into separate directions based on the specific intensity setup. The transmitted beam continues forward, and the reflective beam is angled at 90 degrees. In other words, you can control the amount of reflected and transmitted light, making a beamsplitter ideal for many use cases.

Types of Beamsplitters

Beamsplitters can be divided into two major categories—polarizing and non-polarizing. They are commonly used for polarized isolation, and they can also be used to split unpolarized light in 50/50 ratio. As an example; a Polarizing beamsplitter can reflect S-polarization and transmit P-polarization. Non-polarized beamsplitters do not alter the R/T ratio of the incident light.

Beamsplitters can also operate in different wavelength regions. For example, narrow beamsplitters are commonly used for lasers—since they only operate on a narrow wavelength. Broad wavelength beamsplitters operate across the entire wavelength and are often used for things like broadband.

There are also various types of beamsplitter designs:

- Plate beamsplitters: These thin-coated beamsplitters made of dielectric material are typically used for 45-degree angle incidence. While these beam splitters can be designed to support multiple incident ratios, they produce less chromatic aberration than cube beamsplitters—making them ideal for certain applications.

- Cube beamsplitters: These beamsplitters are formed by coating the hypotenuse of two prisms with a partially reflective coating and joining them together with epoxy or optical cement. These beamsplitters remove ghosting, since the transmitted beam is collinear with the incident beam—which means that there is minimal light offset.

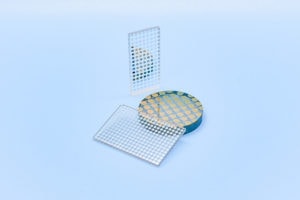

- Polka Dot beamsplitters: These beamsplitters have a polka-dot-like surface. The dots are reflective materials formed by a photolithography process or mechanical masking, and they consist of half of the surface of the beamsplitter—with the other half being transparent (or any ratio desired). This gives them a near-constant R/T ratio that’s not angle-dependent.

Other types include transmission gratings, dichroic, lateral displacement and pellicle beamsplitters.

Beamsplitter Applications

The primary purpose of beamsplitters is to split light (or combine two lights into one) using controlled R/T ratios. This makes them ideal for a variety of applications—including lasers, semiconductors, cameras, and sensors. One common application of beamsplitters is in heads-up displays. These are transparent images that are projected onto a surface (such as a window in an automobile). In typical HUD displays, a beamsplitter is combined with a projection system and lens system to deliver the image via a laser to the surface of the vehicle.

Polarized beamsplitters are often used in applications that require polarization separation (e.g., optical units). For example, cameras and sensors often use polarized beams. Also, beamsplitters are valuable across a wide variety of industries, including:

- Laser systems

- Fiber-optics/Telecommunications

- Interferometers

- Projectors

Beamsplitters From OPCO Laboratory

Founded in 1976, OPCO provides state-of-the-art optical components to industries across the globe. Our best-in-class CNC manufacturing capabilities, coupled with our complete in-house coating capabilities, allow us to produce spectacular optical components using a variety of materials, including:

- Fused silica

- Low and high index glass

- Sapphire

- Calcium fluoride (CaF2)

- Magnesium fluoride (MgF2)

- Zinc selenide (ZnSe)

We also offer a variety of high-quality beamsplitters, including:

- Plate and cube beamsplitters

- Polarizing and non-polarizing beamsplitter

- Dichroic beamsplitter

- Polka-dot beamsplitter

- Lateral displacement beamsplitter

- Custom beamsplitter assemblies

OPCO’s vertically integrated manufacturing capabilities give us complete process control over your product, and we can produce hyper-customized beamsplitters to specific manufacturing needs.

Optical Components and Beamsplitters at OPCO

Beamsplitters are optical components that split light into two. Not only are beamsplitters used across a wide array of consumer tech products (e.g., cameras, projectors, etc.), but they are also useful for analytical instrumentation and industrial systems. OPCO Laboratory, Inc. has been producing optical components—like beamsplitters—for over 40 years, and our state-of-the-art facilities and expert craftspeople help us deliver customized products to a range of industries.

Are you interested in learning more about our optical components? Contact us today.