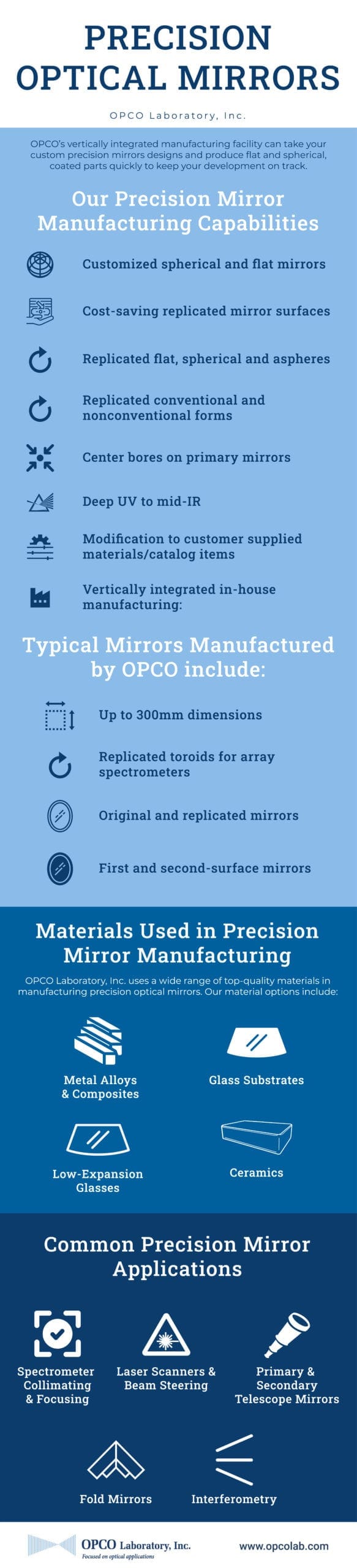

OPCO’s vertically integrated manufacturing facility can take your custom precision mirrors designs and produce flat and spherical, coated parts quickly to keep your development on track.

OPCO has the capability to manufacture your production quantities. Our vertically integrated manufacturing allows us total process control over your product.

Precision Optical Mirror Manufacturing Capabilities

OPCO Laboratory, Inc. has a range of manufacturing capabilities for precision optical mirrors. Our vertically integrated in-house manufacturing allows us to maintain complete process control over your product, from shaping to polishing and coating. This also allows us to achieve high figure repeatability with replicated mirrors as well as perform interferometric and spectrophotometric verification.

We can manufacture a variety of mirror types, including original and replicated. Replication allows us to manufacture optical mirrors at a lower cost. Our replication capabilities include flat, spherical, or aspherical mirrors, along with conventional and non-conventional forms. We can also replicate spectrometer toroids.

Our manufacturing capabilities allow us to manufacture precision mirrors in custom spherical or flat shapes with dimensions up to 300mm. We can produce first and second-surface mirrors, primary mirrors with center bores, and mirrors for wavelengths ranging from deep UV to mid-IR. We can also perform modifications on standard and customer-supplied materials.

Overview of Precision Mirror Manufacturing Capabilities

- Customized spherical and flat mirrors

- Cost-saving replicated mirror surfaces

- Replicated flat, spherical and toroidal

- Replicated conventional and nonconventional forms

- Center bores on primary mirrors

- Deep UV to mid-IR

- Modification to customer supplied materials/catalog items

- Vertically integrated in-house manufacturing:

- Shaping, Polishing, and Coating

- High figure repeatability with replicated mirrors/

- Interferometric and Spectrophotometric verification

Typical Mirrors Manufactured by OPCO include:

- Up to 300mm dimensions

- Replicated toroids for array spectrometers

- Original and replicated mirrors

- First and second-surface mirrors

Materials Used in Precision Mirror Manufacturing

OPCO Laboratory, Inc. uses a wide range of top-quality materials in manufacturing precision optical mirrors. Our material options include:

- Metal Alloys and Composites. We can replicate onto nickel, titanium, ferrous, and aluminum alloys as well as select composites. The replication process offers cost-effectiveness and reduced complexity.

- Glass Substrates. Typical glass substrates, such as Borofloat and Supremax offer chemical resistance while providing high thermal stability.

- Low-Expansion Glasses. Low-expansions glass materials, such as Zerodur, ULE, and fused silica, offer excellent resistance to environmental factors and temperature changes.

- Ceramics. Ceramics like aluminum nitride and silicon carbide are lightweight and offer a low coefficient of thermal expansion.

Common Precision Mirror Applications

Various applications depend on precision mirrors, including:

- Spectrometer Collimating and Focusing. Spectrometers rely on precision mirrors for focusing and collimating light. A concave precision mirror collimates light entering the spectrometer and focuses the beam of light on a grating. Then a second concave precision mirror focuses the light onto the detector.

- Laser Scanners and Beam Steering. A large precision mirror is a vital component of laser scanners and beam steering in the automotive, biometric, and 3D printing fields.

- Primary and Secondary Telescope Mirrors. Telescopes have mirror systems that typically consist of a parabolic primary mirror and a hyperbolic secondary mirror. To ensure optimal performance, it is crucial that these mirrors are free of defects.

- Fold Mirrors. Some mirror systems, such as those within telescopes, have folding mirrors. We can manufacture high-quality precision mirrors for this purpose.

- Interferometry. Precision mirrors are often used as optical flats, which are used as very flat reference surfaces in interferometers to check the flatness of optical elements.

Our optical mirror specialists can help you determine the ideal solution for your application.

Precision Mirrors and Optical Components from OPCO Laboratory, Inc.

At OPCO Laboratory, Inc., we have been manufacturing high-quality precision mirrors since 1976. Our vertical integration grants us optimal control over the production process, from design and fabrication to coating, testing, and more. This allows for quick lead times, lower costs, and higher quality. We are ITAR registered, and our capabilities allow us to meet the expectations of small and large-scale production runs.

For more information, or to get started on your custom precision optical mirror solution, get in touch! Contact Ryan at OPCO to discuss your requirements for mirrors.