OPCO Laboratory, Inc. is your premier partner for comprehensive optical solutions, catering to a wide spectrum of industries and applications. We pride ourselves on being pioneers in optical coating, dielectric coating, optical lens design, optical replication, optical contract manufacturing, and OEM manufacturing support. With our extensive knowledge and industry experience, we serve as your reliable collaborator in the realm of optics.

Our Capabilities

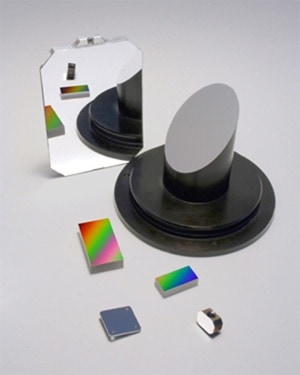

Optical Coatings

OPCO Laboratory excels in delivering high-quality thin film coatings that modify the reflection and/or transmission characteristics of optical components. Our coating expertise ranges from Metal Reflective to Dielectric, Anti-Reflective (AR), Indium Tin Oxide (ITO), Low-Temperature, and Custom coatings.

Our metal reflective coatings increase the reflectivity of optical components, catering to a range of wavelength spectrum. For dielectric coatings, we alter reflectivity by introducing optical interference properties, suiting wavelengths from 190nm to 5µm. AR coatings minimize reflectivity, enhancing transmission with higher contrast. ITO coatings, with their high transparency and electrical conductivity, offer excellent light transmissivity for components needing conductivity without compromising light transmission. We provide low-temperature coatings for heat-sensitive components and also specialize in custom coatings for unique requirements.

Using ion-assisted deposition, e-beam, and resistive evaporation technologies, we apply these coatings with meticulous precision. Whether for broadband wavelength beamsplitters, laser components, electromagnetic interference (EMI) shielding, or sensitive glass and polycarbonate surfaces, OPCO’s 40 years of experience assure superior results at competitive prices.

We’re more than a service provider; we’re a partner in your success. Our commitment to quality, precision, and customer satisfaction sets us apart. Contact us at OPCO for your optical coating requirements. Learn more here

Quick Turn Prototype Program

The Quick Turn Prototype Program is a unique service we offer to help our clients fast-track their projects. We understand that in the world of optics, prototyping is often a crucial step in the development process. This program provides expedited prototype development while maintaining our stringent quality and performance standards, with the aim of delivering finished products in 1-2 weeks ARO, depending on complexity.

Our dedicated team works closely with your project requirements, ensuring quick turnaround times without compromising on precision and quality. The quick turn prototype program is an embodiment of our commitment to delivering exceptional service while meeting your project timelines.

Further to these capabilities, our Quick Turn Prototype Program stands as a testament to our customer-centric approach. We’ve designed the process to be highly flexible, adjusting to fit different needs and accommodating specific design changes in the middle of the prototyping process.

Leveraging cutting-edge technology, we can create sophisticated prototypes that give a tangible, real-world perspective on your design. These prototypes serve as an invaluable tool for detailed analysis and refinement before proceeding to full-scale production. Learn more here

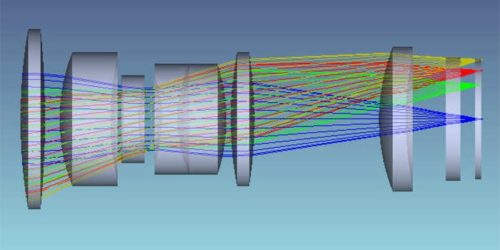

Custom Design Assistance

At OPCO, we go beyond the ordinary; we are collaborators and innovators. Our expertise in Custom Design Assistance is embedded in our commitment to helping you throughout the lifecycle of your project. Our team of highly skilled optical engineers works in partnership with you to design, optimize, and test bespoke optical lens designs.

Our experience ranges from manufacturing custom lenses and domes, using our in-house capabilities to grind and polish spherical optics, to providing optical solutions for various industries, including the military and defense. We pride ourselves on being able to deliver your custom requirements when you need them, thanks to our vertically integrated manufacturing that offers total process control over your product.

Our deep industry knowledge and advanced computational tools enable us to deliver high-quality, cost-effective solutions tailored to your specific needs. Our expertise extends to a wide range of optical products such as lenses, laser prisms, optical testing tools, and laser windows used in a variety of applications, including, but not limited to, forward-looking infrared, night vision optics and infrared filters, missile guidance systems, and laser optics for nuclear defense applications.

We also offer extensive testing services to validate your design’s performance under various conditions. To reduce lead times, we maintain an inventory of the most popular raw materials. At OPCO, our commitment to partnership means working with you every step of the way, from concept to refinement, to bring your optical vision to life. With OPCO, trust a proven leader for optical product manufacturing, prototyping, and design. Learn more here

Replication Services and Masters

OPCO offers superior Replication Services and Masters, providing a cost-effective solution for the high-volume manufacturing of complex optics. We harness advanced technologies such as single-point diamond turning and direct laser writing to fabricate masters and replicate optics like mirrors and amplitude gratings. Our process includes manufacturing a “master” using conventional machining, grinding, and polishing techniques. Following validation, we apply a release agent and the necessary coatings before applying an engineered polymer epoxy. This process enables the creation of high-accuracy components with a fraction of the processing time compared to conventional methods.

The replication services we provide are beneficial for applications requiring precision optical components, offering the potential for reduced system weight, improved stability, and faster assembly. Our replicated optics are suited to applications operating in the range of -40°C to +125°C due to the polymer epoxy used. Additionally, the process allows for mounting holes, tabs, and unique shapes to be incorporated into the components, significantly reducing cost, size, and weight for OEMs.

With OPCO, you can expect precision, speed, and value at every stage of the optical replication process, from the creation of precision masters to the final replication of optical components. Learn more here

Contract Manufacturing

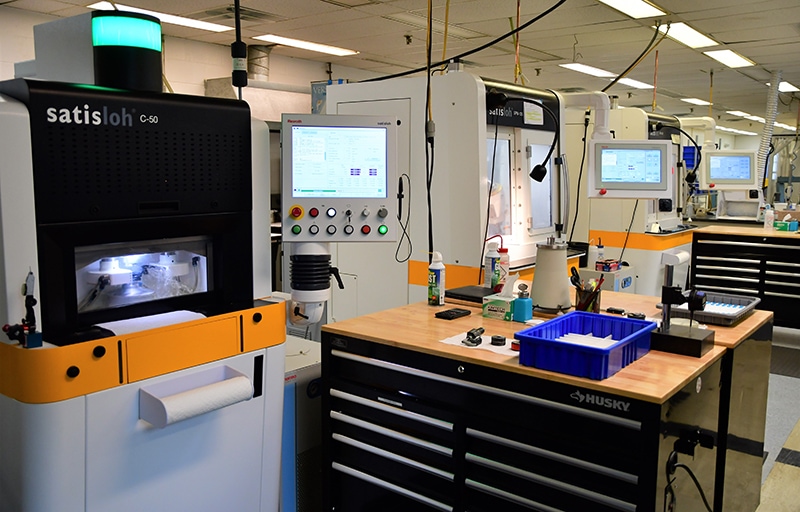

OPCO’s Optical Contract Manufacturing services, supported by our advanced manufacturing facility and team expertise, cater to a variety of optical component needs. We ensure that our products, ranging from simple lens barrels to fully integrated optical sub-assemblies, comply with the highest industry standards. Our service includes in-house engineering, prototyping, subsystem production, and testing using cutting-edge technology such as autocollimators, interferometers, spectrophotometers, and laser systems.

Whether you need custom lenses, prisms, mirrors, or any other optical components, OPCO can deliver optimum performance, on-time delivery, and competitive pricing. We have the capability to manufacture in small to large production volumes, offering flexibility and scalability. Our turnkey solutions can be seamlessly integrated into your existing supply chain, positioning us as an extension of your operation.

Our vast fabrication capabilities include 5-axis CNC machining, micro-dicing, surface grinding, and both small and large-capacity spindle polishing. We maintain and utilize state-of-the-art equipment to produce precision custom optics tailored to your specifications.

At OPCO, we are committed to your success, offering quality, cost-effective assembly, and flexible manufacturing capabilities for diverse applications, including camera systems, metrology instruments, medical devices, and more. Learn more here

OEM Lifecycle Support Program

The OPCO OEM Lifecycle Support Program is an initiative designed to accompany your company’s journey from conception to manufacturing, and beyond. It encapsulates four key phases: Initial Concept, Design and Prototype, Development, and Manufacturing Ramp. Throughout these stages, we work closely with you to optimize performance, cost, and delivery to meet your program’s objectives.

Our support program is robust and flexible, catering to the dynamic nature of today’s market. It allows for effective adaptation to changes, including regulatory shifts, market fluctuations, or technological advancements.

Leveraging our 40-year experience in the optics industry, we offer full in-house design, testing, manufacturing, and assembly capabilities. This empowers us to anticipate and handle potential challenges proactively, minimizing disruptions and ensuring seamless operations.

Moreover, we provide comprehensive training and technical support, aiding your team in understanding and maintaining optical components effectively. The OPCO OEM Lifecycle Support Program goes beyond product delivery, forming a sustainable partnership that bolsters your long-term success. Our commitment echoes our core values of integrity, quality, and dedication. Learn more here

Our comprehensive optical contract manufacturing capabilities combined with our deep understanding of optics make OPCO Laboratory, Inc. the preferred choice for all your optical needs. We are committed to delivering precision, quality, and innovation at every stage, ensuring your objectives are met with unrivaled expertise and dedication.