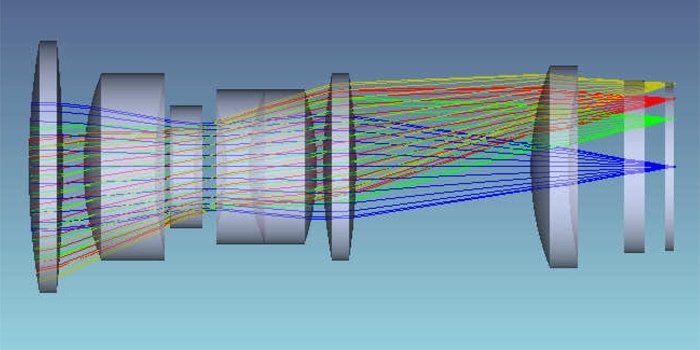

Custom Lens Manufacturing

Using our in-house capabilities to grind and polish spherical optics, our experienced craftsmen will deliver your custom lenses and domes when you need them.

OPCO has the capability to manufacture your production quantities. Our vertically integrated manufacturing allows us total process control over your product.

Custom Optical Solutions for Military and Defense

OPCO is proud to serve our military and defense customers. We have supplied products for precision light management, including optical lenses, laser prisms, optical testing tools, and laser windows for several applications. Some examples include:

- Forward-looking infrared

- Military lasers

- Night vision optics and infrared filters for soldiers

- Missile guidance systemss

- Laser optics for nuclear defense applications

- Targeting systems

- High-quality, lightweight aspherical lenses for use in surveillance devices

- Optical glass for fingerprint and retinal scanning devices

- Thermal imaging

- Anti-reflective coatings for optic devices

- Scientific optical instruments

OPCO’s engineers and technical staff understand the unique needs and challenges of the military and defense industries. The latest technology in coating for military optics and photonics is critical to ensure that light reflection does not cause the user to be detected. Features like night vision must be durable and compact, as well as have superior clarity. Filters must transmit certain wavelengths while reflecting unwanted ones

OPCO Laboratory, Inc. is an ITAR registered facility. Our capabilities for military and defense optics include beamsplitters, diffraction gratings, mirrors, lenses and domes, windows and prisms, as well as replication services and masters.

Typical Lenses & Domes Manufactured by OPCO Include:

- Spherical Lenses 2mm — 300mm

- Hemi-Spherical Lenses 2mm — 300mm

- Hyper-Spherical Lenses 2mm — 100mm

- Aspherical Lenses 2mm — 100mm

- Plano Concave/Convex Lenses 2mm — 300mm

- Double Concave/Convex Lenses 2mm — 300mm

- Drum Lenses 2mm — 35mm diameter

- Ball Lenses 2mm — 25mm diameter

- Cylindrical Lenses 2mm — 500mm radius

- Doublet & Triplet Lenses 2mm — 300mm

- Domes 2mm — 75mm diameter

Materials

- Fused Silica

- Low and High Index Glass

- Silicon (Si)

- Germanium (Ge)

- Sapphire

- Calcium Fluoride (CaF2)

- Magnesium Fluoride (MgF2)

- Zinc Selenide (ZnSe)

To reduce lead times we maintain an inventory of the most popular raw materials.

Specifications

- Surface Quality to 10-5

- Surface Accuracy to λ/10

- Angles (Wedge or Prism) down to seconds

- Centration within seconds

- Tolerances 10 microns

Precision Lenses manufactured exactly to your specification

- Skilled opticians employ CNC manufacturing to ensure consistency in specs.

- Unique in-house capability to manufacture Test Plates assures lens radius, surface accuracy, and repeatability — a cost and time advantage during the design phase.

- Centration within seconds, validated by our computer controlled centering scope.

- Angles are maintained using high resolution autocollimators.

Other Industries and Applications for Custom Lenses

OPCO can create custom lenses for a range of non-military or defense industries and applications, as well.

Research/Life Science

Life sciences and research is a vast field. Optic needs can span from camera lenses to 3D imaging lenses and super resolution microscopy. Our capabilities in this field include optical spectroscopy, environmental analyzers, veterinary diagnostics, atomic force microscopes, optical profilers, cell analyzers or flow cytometry, DNA analyzers, and immunoassay readers.

Semiconductors

Cutting-edge inspection tools are in high demand where accuracy and precision are essential for wafer inspection. High resolution optical assemblies and custom optics that operate with the utmost precision are required to work with a variety of illumination and modalities.

Spectroscopy

Where the optical spectrum is to be analyzed by its absorption, scattering, or emission, only a manufacturer with an understanding of and expertise in spectroscopy will suffice. Our laboratory supplies components for equipment used to measure toxic compounds in blood samples, the measurement of different compounds in food samples by absorption spectroscopy both in the visible and infrared spectrum, the non-destructive elemental analysis by X-ray fluorescence, estimating weathered wood exposure times using near infrared spectroscopy, electronic structure research with various spectroscopes, and cure monitoring of composites using optical fibers.

Optical Product Manufacturing, Prototyping, and Design Expertise from OPCO Laboratory, Inc.

OPCO Laboratory, Inc. specializes in designing and manufacturing of optical components and optical assemblies. Our extensive experience, state-of-the-art fabrication equipment, and ITAR-registered facility, combined with over 40 years of industry expertise, enable us to produce high-quality optical solutions for our customers in the aerospace, defense, life sciences, and semiconductor industries, among many others.

To learn more about our products, we invite you to review our product page. For questions or to get started on your next solution, contact us today.